Washpipe Seal Assembly

During a drilling operation, fluids are circulated to flush out matter from the wellbore. A washpipe assembly allows for a fluid seal between the stationary and nonrotating component of the swivel or top drive and the rotating upper end of the drill stem. The more pressure a washpipe handles, the more effective the flushing process.

The largest manufacture of waspipes and power swivels in the world engaged Clark Seals to develop a washpipe seal that exceeded 10,000 PSI, thereby eclipsing the previous limit of 7500 PSI and giving them the strongest power swivel in the industry. The problem is, at 10,000 PSI rubber extrudes through a hairline crack, so traditional materials and sealing technologies would not work.

Clark Seals’ engineers created an innovative sealing assembly that combined a ceramic sealing surface, a spring-biased floating guide and a secondary and abrasive resistant elastomeric seal, resulting in a wash pipe seal assembly that created exceptional durability under extreme pressure and RPM conditions, Serviceability through detachable components, and cost-effective service life with reversible sealing surfaces.

In the end, Clark Seals Washpipe Seal Assembly nearly doubled the customers benchmark of 10,000 PSI, and and represented a significant improvement over traditional elastomer-only seal stacks, delivering enhanced longevity and performance in demanding drilling applications.

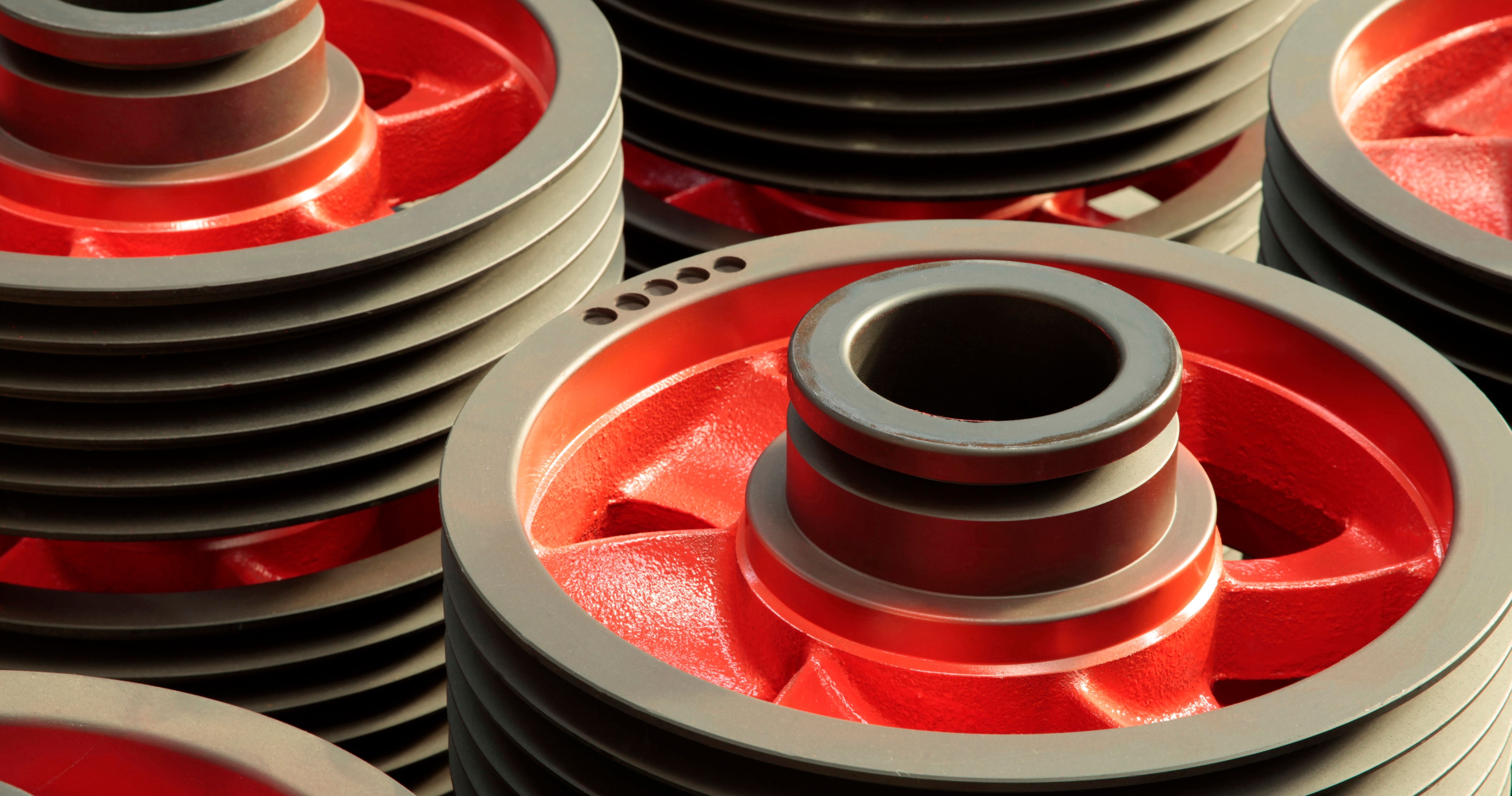

| Product Name | Sheave Seal | ||

|---|---|---|---|

| Product Description | Patented Hand-Install Sheave Seal | ||

| Capabilities Applied/Processes | Problem Seal Analysis | Precision Manufacturing | Custom AutoCAD Seal Design |

| Manufacturing Equipment Used | Tapered Roller Bearing Sheave | ||

| Overall Dimensions of the Seal | Ö6.503 x 0.437 (OD x H) | ||

| Tightest Tolerances Met | RMA standards, .001" | ||

| Material Used | ELASTOMER: NITRILE | METAL CASE: Carbon Steel | |

| Features | Patented Hand-Install Design | ||

| Benefits | Resists Compression Set and Stress Relaxation @ Low | Remains More Flexible During Long Periods of Idleness | Elastomer with low friction coefficient ingredients. |

| In process testing performed | Field Testing | ||

| Estimated Part Weight | 0.236 lbs | ||

| Standards Met | Nitrile resp. ASTM D2000 M2BG 714 | Metal case material spec.: SAE 1008 | |

| Industry for Use | Oil & Gas | ||

| Delivery Location | United States and around the world |

Precision Sealing, Engineered

for Excellence.

For 70 years, Clark Seals has partnered with manufacturers in various industries to provide industry-leading products, services and supply-chain assistance.

Contact Us