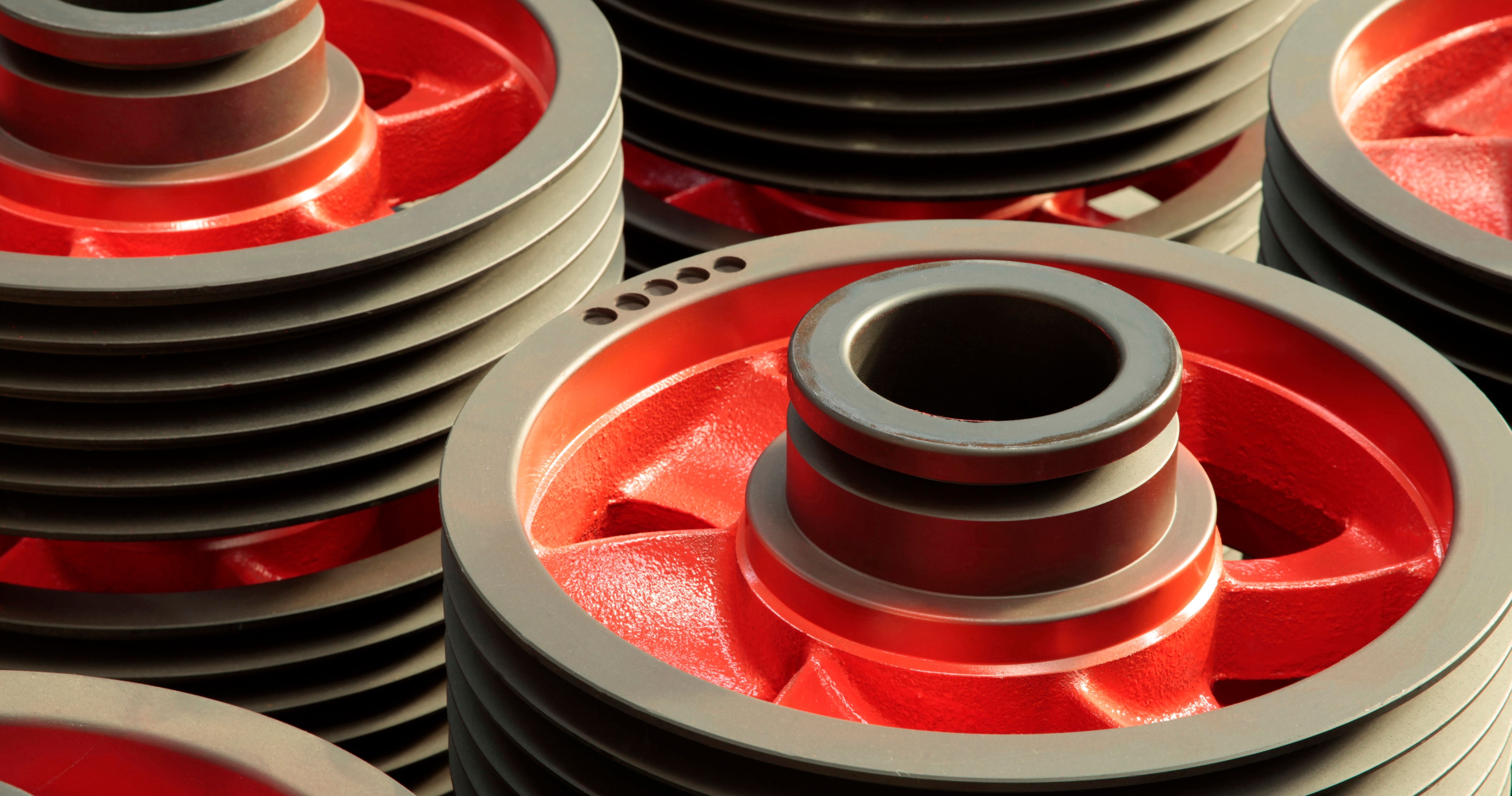

Custom Designed; Manufactured Nitrile Mechanical Seal for Washing Machine Tub

Clark Seals, was approached by the largest manufacturer of commercial laundry equipment to address a seal leakage issue in sandy environments. Sand particles were entering between the sealing surfaces of the mechanical seal, causing face grooving and resulting in leakage.

To resolve the problem, we designed a custom two-piece integrated sealing solution that sealed both the top and bottom of the tub. The top seal was engineered to press-fit around the tub bearing, improving alignment between the transmission, tub, and agitator, while featuring a triple sealing lip to prevent water, sand, and debris from entering the bearing cavity. The bottom seal was designed with a locking pin to resist torque and press-fit into the top seal during installation. To further combat the intrusion of sand and contaminants, our engineers developed and patented a unique negative "R" sealing lip geometry. This innovative design allowed the sprung lip to function as an excluder lip, effectively keeping all sand and debris out of the sealing environment.

The result was a patented sealing solution that eliminated warranty claims, reduced costs by 80%, and lasted more than 700% longer than the original mechanical seal it replaced.

| Product Name | Washing Machine Tub Seal | ||

|---|---|---|---|

| Product Description | Custom two-piece integrated washing machine tub seal. | ||

| Manufacturing Equipment Used | Commercial Vertical Washing Machine | ||

| Overall Dimensions of the Seal | Ö3.630x1.150 (OD xH assembled dimension) | ||

| Tightest Tolerances Met | RMA standards, .001" | ||

| Material Used | ELASTOMER:Nitrile | SPRING: Stainless steel | METAL CASE: carbon steel |

| Benefits | Eliminated Warranty Claims | 80% Cost Savings | Lasts 700% Longer than the Seal it Replaced |

| In process testing performed | Inspected Each Assembly | After Insertion of the Bearing into the Bottom Seal for Rotation and Assembled Dimensions | Customer Life-Test |

| Estimated Part Weight | 0.8935lbs | ||

| Standards Met | Elastomer spec.: SAE J200, JMLU2 and UL157 | Metal case material spec.: SAE 1008 | Spring material spec.: SAE 30304 |

| Industry for Use | Laundry Equipment | ||

| Delivery Location | Ripon,Wisconsin |

Precision Sealing, Engineered

for Excellence.

For 70 years, Clark Seals has partnered with manufacturers in various industries to provide industry-leading products, services and supply-chain assistance.

Contact Us